PRODUCT CATEGORIES

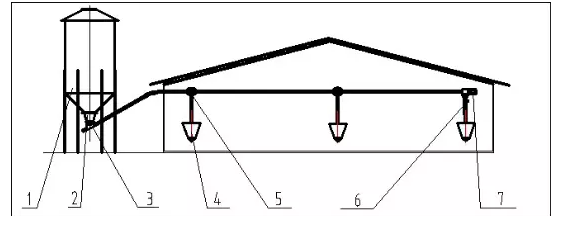

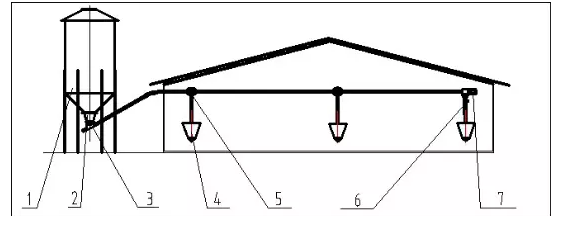

Feed storage farm silo consist of main warehouse, flip, ladders, columns and other components. This system include feed silo or hopper, conveying PVC pipe, auger or chain - disc, drop outlets, feed bin, feed sensor and driving motor.This system is mainly used to convey feed from the feed silo or hopper into the feed bin to achieve the aim of automatically feeding.

The main warehouse used 275g/m2, double hot dip galvanized sheet steel, has a lower conical holes to view feed level. Feed silo volume according to different actual combinations.Hoarding water in a slope, in the hoarding at the bottom flange, so that rain water away from the cutting area. Provide weather protection , regardless of the weather. the next round head screw connection cone inside, effectively reducing cutting resistance. Upper and lower cone by pressure off treatment,both to improve the cone and strength of cone bottom's overall, but also conducive to bilateral clay bar installation , enhanced sealing.

| Model | Capacity | Weight(Kg) | Overall Height(m) | Diameter(m) |

| QK-LC001 | 3ton | 3.00 | 3.8 | 1.80 |

| QK-LC002 | 5ton | 4.20 | 4.7 | 2.45 |

| QK-LC003 | 8ton | 4.70 | 5.6 | 2.45 |

| QK-LC004 | 10ton | 6.00 | 5.6 | 2.75 |

| QK-LC005 | 15ton | 6.40 | 5.6 | 3.10 |

| QK-LC006 | 16ton | 6.55 | 6.5 | 2.80 |

| QK-LC007 | 20ton | 7.55 | 6.5 | 3.10 |

The 3D design of feed silo

The part of QunKun factory

| Model | Capacity | Weight(Kg) | Overall Height(m) | Diameter(m) |

| QK-LC001 | 3ton | 3.00 | 3.8 | 1.80 |

| QK-LC002 | 5ton | 4.20 | 4.7 | 2.45 |

| QK-LC003 | 8ton | 4.70 | 5.6 | 2.45 |

| QK-LC004 | 10ton | 6.00 | 5.6 | 2.75 |

| QK-LC005 | 15ton | 6.40 | 5.6 | 3.10 |

| QK-LC006 | 16ton | 6.55 | 6.5 | 2.80 |

| QK-LC007 | 20ton | 7.55 | 6.5 | 3.10 |

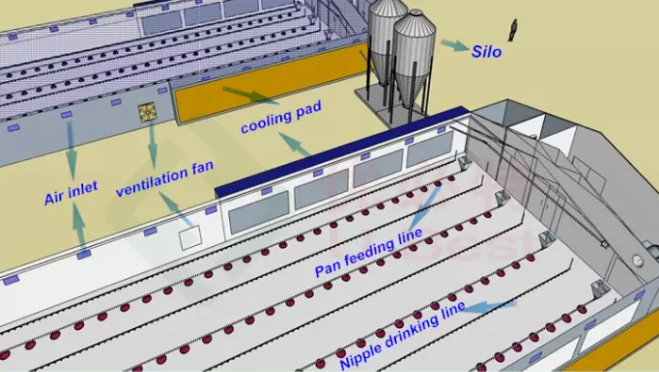

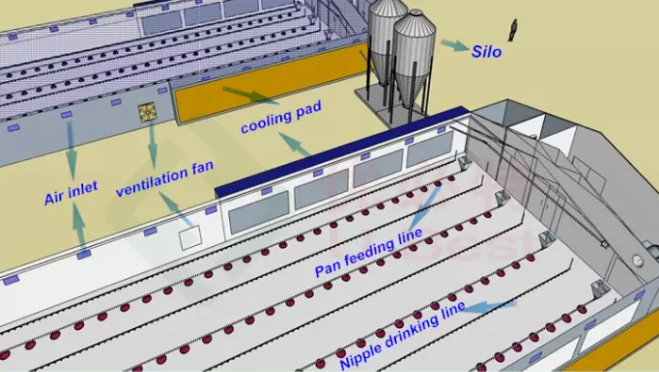

The 3D design of feed silo

The part of QunKun factory

(* Guarantee your email safe absolutely)